Millennium Pharmaceuticals, Inc.

Millennium Pharmaceuticals, Inc. INNOVATOR

Millennium Pharmaceuticals, Inc., a subsidiary of Takeda Pharmaceutical Company Limited,

MLN4924, MLN 4924-003, TAK-924

905579-51-3 BASE

1160295-21-5 HcL

A

potent and selective inhibitor of NAE. An inhibitor of NEDD8-activating

enzyme as a new approach to treat cancer. The ubiquitin-proteasome

pathway mediates the destruction of unwanted proteins.

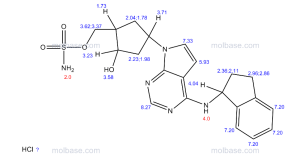

(((1

S,2

S,4

R)-4-{4-[(

S)-2,3-Dihydro-1

H-inden-1-ylamino]-7

H-pyrrolo[2,3-

d]pyrimidin-7-yl}-2-hydroxycyclopentyl)methyl

sulfamate hydrochloride) (pevonedistat), a novel NEDD8-activating

enzyme (NAE) inhibitor, has demonstrated in vitro cytotoxic activity

against a variety of human malignancies and is currently being developed

by Takeda Pharmaceuticals Company Limited as a clinical candidate for

the treatment of cancer

In 2011, orphan drug designation was

assigned to MLN-4924 for the treatment of MDS and for the treatment of

acute myelogenous leukemia.

PHASE 1.......CANCER SOLID TUMOR

......................

PATENT

http://www.google.com/patents/US20120330013

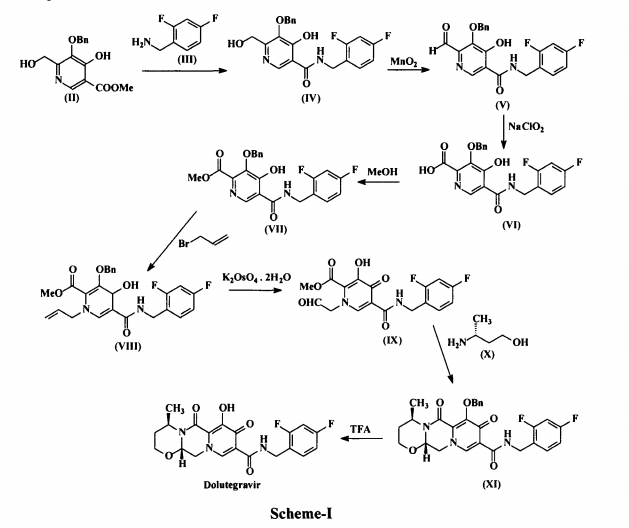

preparing a compound represented by the following formula 1 by reacting the compound of formula 11 with TFA (step 9):

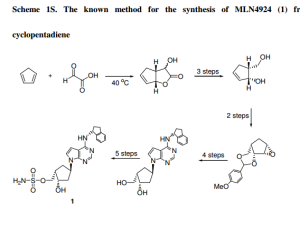

The retrosynthetic analysis of MLN4924 (1), as the final desired nucleoside, is shown in the following.

MLN

4924 (1) can be synthesized by condensing cyclic sulfate 3 as the

glycosyl donor with a purine base. The glycosyl donor 3 can be produced

from diol 4, which in turn can be obtained from cyclopentanone 5 via a

stereoselective reduction and a regioselective cleavage of the

isopropylidene moiety. The cyclopentanone 5 can be synthesized from

cyclopentenone 6 by stereoselective reduction. The intermediate

cyclopentenone 6 can be easily derived from D-ribose according to our

previously published procedure (Jeong, L. S. et al., J. Org. Chem. 2004,

69, 2634-2636).

The synthetic route for the glycosyl donor 3 is shown in the following scheme 1.

Example

1 Preparation of MLN4924 Step 1: Preparation of

6-(tert-butyl-diphenyl-silanyloxymethyl)-2,2-dimethyl-tetrahydro-cyclopenta[1,3]dioxol-4-one

(Compound 5)

To

a suspension of the compound 6 (20.0 g, 47.1 mmol) in methanol (400 ml)

was added 10% palladium on activated carbon (1.0 g), and the mixture

was stirred at room temperature overnight under H2 atmosphere.

After filtration of the reaction mixture, the solvent was removed and

the residue was dissolved in methylene chloride and then filtered

through short pad silica gel. Then, the solvent was evaporated to give

the compound 5 (20.1 g, 100%) as a colorless syrup.

[α]20 D −28.32 (c 1.49, MeOH); HR-MS (ESI): m/z calcd for C25H32NaO4Si [M+Na]+ 447.1968, Found 447.1956; 1H NMR (400 MHz, CDCl3)

δ 7.69 (m, 4H), 7.40 (m, 6H), 4.84 (t, J=4.4 Hz, 1H), 4.22 (dd, J=1.2,

4.8 Hz, 1H), 3.96 (dd, J=8.0, 10.0 Hz, 1H), 3.82 (dd, J=6.8, 10.0 Hz,

1H), 2.37 (m, 1H), 2.30 (ddd, J=1.2, 8.4, and 18.4 Hz, 1H), 2.20 (ddd,

J=1.2, 12.0, and 18.4 Hz, 1H), 1.37 (s, 3H), 1.35 (s, 3H), 1.06 (s, 9H);

13C NMR (100 MHz, CDCl3) δ 112.6, 80.5, 77.6, 77.2, 76.9, 63.6, 38.1, 36.9, 27.1, 27.02, 27.01, 25.3, 19.5; Anal. Calcd for C25H32O4Si: C, 70.72; H, 7.60. Found: C, 70.79; H, 7.75.

Step 2: Preparation of 6-(tert-butyl-diphenyl-silanyloxymethyl)-2,2-dimethyl-tetrahydro-cyclopenta[1,3]dioxol-4-ol (Compound 7)

To

a suspension of the compound 5 (20.1 g, 47.1 mmol) in methanol (500 ml)

were added sodium borohydride (2.17 g, 57.4 mmol) and cerium (III)

chloride heptahydrate (21.3 g, 57.2 mmol) at 0° C., and the mixture was

stirred at room temperature for 30 min. After the solvent was removed,

the residue was partitioned between ethyl acetate and water. The organic

layer was then washed with brine, dried with anhydrous MgSO4,

filtered, and evaporated. The residue was purified by silica gel column

chromatography (hexane/ethyl acetate=5/1) to give the compound 7 (20.86

g, 98%) as a colorless syrup.

[α]20 D +34.55 (c 0.55, MeOH); HR-MS (ESI): m/z calcd for C25H34NaO4Si [M+Na]+: 449.2124; Found: 449.2110; 1H NMR (400 MHz, CDCl3)

δ 7.69 (m, 4H), 7.39 (m, 6H), 4.62 (t, J=5.6 Hz, 1H), 4.44 (t, J=5.6

Hz, 1H), 3.89 (dd, J=6.0, 7.6 Hz, 1H), 3.84 (m, 1H), 3.68 (dd, J=6.4,

10.0 Hz, 1H), 1.91 (m, 2H), 1.26 (m, 1H), 1.42 (s, 3H), 1.33 (s, 3H),

1.05 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 135.9,

135.8, 134.2, 134.1, 129.8, 129.7, 127.8, 127.7, 110.6, 79.4, 78.9,

77.6, 77.2, 76.9, 72.5, 62.9, 41.6, 33.4, 27.0, 25.9, 27.0, 25.9, 24.4,

19.5; Anal. Calcd for C25H34O4Si: C, 70.38; H, 8.03. Found: C, 70.41; H, 8.08.

Step 3: Preparation of 3-tert-butoxy-4-(tert-butyl-diphenyl-silanyloxymethyl)-cyclopentane-1,2-diol (Compound 4)

To

a solution of the compound 7 (20.86 g, 47.12 mmol) in methylene

chloride was added trimethylaluminum (2.0 M in toluene, 132.1 ml) at 0°

C., and the mixture was stirred at room temperature for 2 days. The

mixture was cooled to 0° C., slowly quenched with an aqueous saturated

ammonium chloride solution, filtered, and evaporated. The residue was

partitioned between ethyl acetate and water. The organic layer was

washed with brine, dried with anhydrous MgSO4, filtered, and

evaporated. The residue was purified by silica gel column chromatography

(hexane/ethyl acetate=2/1) to give the compound 4 (13.42 g, 62%) as a

colorless syrup.

[α]20 D +3.30 (c 0.55, MeOH); HR-MS (ESI): m/z calcd for C26H38NaO4Si [M+Na]+: 465.2437; Found: 465.2423; 1H NMR (400 MHz, CDCl3)

δ 7.70 (m, 4H), 7.41 (m, 6H), 4.05 (dd, J=4.4, 7.2 Hz, 1H), 3.93 (m,

1H), 3.72 (m, 2H), 3.59 (dd, J=3.6, 12.0 Hz, 2H), 2.70 (d, J=20.8 Hz,

1H), 2.10 (m, 2H), 1.60 (m, 1H), 1.20 (s, 9H), 1.06 (s, 9H); 13C NMR (100 MHz, CDCl3)

δ 135.9, 133.5, 130.0, 129.9, 127.9, 127.9, 77.6, 77.2, 76.9, 74.9,

73.8, 72.7, 72.1, 63.3, 42.1, 34.0, 28.5, 27.0, 19.4; Anal. Calcd for C26H38O4Si: C, 70.55; H, 8.65. Found: C, 70.61; H, 8.70.

Step

4: Preparation of

(4-tert-butoxy-2,2-dioxo-tetrahydro-2-yl-6-cyclopenta[1,3,2]-dioxathiol-5-ylmethoxy)-tert-butyl-diphenyl-silane

(Compound 3)

To

a solution of the compound 4 (13.42 g, 30.3 mmol) in methylene chloride

were added triethyl amine (14.5 ml, 101.0 mmol) and thionyl chloride

(3.7 ml, 47.4 mmol) at 0° C., and the reaction mixture was stirred at 0°

C. for 10 minutes. The reaction mixture was partitioned between

methylene chloride and water. The organic layer was washed with brine,

dried with anhydrous MgSO4, filtered, and evaporated. The

residue was purified by silica gel column chromatography (hexane/ethyl

acetate=6/1) to give the cyclic sulfite (14.37 g, 97%) as a white foam.

[α]20 D +20.00 (c 0.05, MeOH); HR-MS (ESI): m/z calcd for C26H36NaO5SSi [M+Na]+: 511.1950; Found: 511.1929; 1H NMR (400 MHz, CDCl3)

δ 7.64 (m, 4H), 7.40 (m, 6H), 5.23 (m, 1H), 5.04 (dd, J=4.4, 6.0 Hz,

1H), 4.01 (t, J=4.8 Hz, 1H), 3.68 (dd, J=3.6, 10.4 Hz, 1H), 3.56 (dd,

J=8.0, 10.4 Hz, 1H), 2.07 (m, 2H), 1.96 (m, 1H), 1.14 (s, 9H), 1.05 (s,

9H); 13C NMR (100 MHz, CDCl3) δ 135.8, 135.7,

133.9, 133.8, 129.9, 129.9, 127.9, 127.8, 85.7, 83.2, 77.6, 77.2, 76.9,

75.0, 71.1, 62.7, 44.7, 31.4, 28.5, 27.1, 19.4; Anal. Calcd for C26H36O5SSi: C, 63.90; H, 7.42; S, 6.56. Found: C, 63.94; H, 7.45; S, 6.61.

To

a solution of the cyclic sulfite obtained above (14.37 g, 29.4 mmol) in

the mixture of carbon tetrachloride, acetonitrile and water (1:1:1.5,

210 ml) were added sodium metaperiodate (18.56 g, 56.4 mmol) and

ruthenium chloride (1.72 g, 8.25 mmol), and the reaction mixture was

stirred at room temperature for 10 minutes. The reaction mixture was

partitioned between methylene chloride and water. The organic layer was

washed with brine, dried with anhydrous MgSO4, filtered, and

evaporated. The residue was purified by silica gel column chromatography

(hexane/ethyl acetate=4/1) to give the compound 3 (13.36 g, 90%) as a

white solid.

mp 101-104° C.; [α]20 D −80.00 (c 0.05, MeOH); HR-MS (ESI): m/z calcd for C26H36NaO6SSi [M+Na]+: 527.1900; Found: 527.1881; 1H NMR (400 MHz, CDCl3)

δ 7.64 (m, 4H), 7.41 (m, 6H), 5.13 (m, 1H), 4.83 (dd, J=4.4, 6.8 Hz,

1H), 4.13 (t, J=4.0 Hz, 1H), 3.92 (dd, J=6.4, 10.4 Hz, 1H), 3.69 (dd,

J=5.2, 10.4 Hz, 1H), 2.11 (m, 2H), 2.02 (m, 1H), 1.15 (s, 9H), 1.05 (s,

9H); 13C NMR (100 MHz, CDCl3) δ 135.7, 135.0,

133.8, 133.7, 130.0, 128.0, 127.9, 83.5, 82.2, 77.6, 77.2, 76.9, 75.4,

70.4, 70.4, 62.2, 43.9, 31.3, 28.2, 27.1, 26.8, 19.4; Anal. Calcd for C26H36O6SSi: C, 61.87; H, 7.19; S, 6.35. Found: C, 61.91; H, 7.14; S, 6.30.

Step

5: Preparation of

2-tert-butoxy-3-(tert-butyl-diphenyl-silanyloxymethyl)-5-[4-(indan-1-ylamino)-pyrrolo[2,3-d]pyrimidin-7-yl]-cyclopentanol

(Compound 8)

A suspension of N6-indanyl-7-deazaadenine

(8.80 g, 35.2 mmol), sodium hydride (1.38 g, 45.7 mmol) and 18-crown-6

(9.11 g, 45.7 mmol) in THF (200 ml) was stirred at 80° C. To the

reaction mixture was added a solution for the compound 3 (13.36 g, 26.5

mmol) in THF (150 ml), and the stirring was continued at 80° C.

overnight. The reaction mixture was cooled down to 0° C., and conc. HCl

was added slowly until pH reaches 1-2. Then the reaction mixture was

further stirred at 80° C. for 2 hours. After neutralized with saturated

aqueous NaHCO3 solution, the reaction mixture was partitioned

between ethyl acetate and water. The organic layer was washed with

brine, dried with anhydrous MgSO4, filtered, and evaporated.

The residue was purified by silica gel column chromatography

(hexane/ethyl acetate=2/1) to give the compound 8 (11.62 g, 65%) as a

white foam.

UV (CH2Cl2) λmax 272.5 nm; [α]20 D −8.89 (c 0.45, MeOH); HR-MS (ESI): m/z calcd for C41H51N4O3Si [M+H]+: 675.3730; Found: 675.3717; 1H NMR (400 MHz, CDCl3)

δ 8.38 (s, 1H), 7.70 (m, 4H), 7.41 (m, 6H), 6.92 (d, J=3.6 Hz, 1H),

6.29 (d, J=3.2 Hz, 1H), 5.91 (dd, J=7.6, 14.8 Hz, 1H), 5.14 (br d, J=6.8

Hz, 1H), 4.77 (m, 1H), 4.36 (t, J=6.0 Hz, 1H), 4.22 (dd, J=5.2, 10.8

Hz, 1H), 3.84 (dd, J=5.6, 10.4 Hz, 1H), 3.73 (dd, J=8.4, 10.4 Hz, 1H),

3.37 (d, J=5.6 Hz, 1H), 3.06 (m, 1H), 2.95 (m, 1H), 2.75 (m, 1H), 2.75

(m, 1H), 2.58 (m, 1H), 2.38 (m, 1H), 2.15 (m, 1H), 1.98 (m, 1H), 1.65

(s, 1H), 1.55 (s, 1H), 1.16 (s, 9H), 1.07 (s, 9H); 13C NMR (100 MHz, CDCl3)

δ 156.4, 151.8, 150.3, 144.1, 143.8, 135.9, 134.0, 129.9, 128.2, 127.9,

127.9, 127.0, 125.1, 124.4, 123.3, 103.8, 97.4, 77.8, 77.6, 77.2, 76.9,

74.9, 72.4, 63.5, 62.1, 56.3, 43.9, 34.9, 30.5, 30.5, 28.5, 27.2, 19.5;

Anal. Calcd for C41H50N4O3Si: C, 72.96; H, 7.47; N, 8.30. Found: C, 73.01; H, 7.45; N, 8.36.

Step

6: Preparation of

{7-[3-tert-butoxy-4-(tert-butyl-diphenyl-silanyloxymethyl)-cyclopentyl]-7H-pyrrolo[2,3-d]pyrimidin-4-yl}-indan-1-yl-amine

(Compound 9)

To

a solution of the compound 8 (11.62 g, 17.2 mmol) in methylene chloride

(300 ml) were added N,N-dimethylaminopyridine (5.64 g, 51.6 mmol) and

phenyl chlorothionocarbonate (4.3 ml, 34.4 mmol), and the reaction

mixture was stirred at room temperature overnight. After the solvent was

removed, the residue was purified by silica gel column chromatography

(hexane/ethyl acetate=6/1) to give the thiocarbonate (13.82 g, 99%) as a

white foam.

UV (MeOH) λmax 271.50 nm; [α]20 D +10.00 (c 0.15, MeOH); HR-MS (ESI): m/z calcd for C48H55N4O4SSi [M+H]+: 811.3713; Found: 811.3687; 1H NMR (400 MHz, CDCl3)

δ 8.36 (s, 1H), 7.61 (dd, J=1.6, 7.6 Hz, 4H), 7.34 (m, 5H), 7.26 (m,

4H), 7.18 (m, 6H), 6.86 (s, 1H), 6.25 (d, J=3.2 Hz, 1H), 6.00 (dd,

J=3.2, 8.4 Hz, 1H), 5.83 (d, J=6.8 Hz, 1H), 5.19 (m, 1H), 5.07 (br s,

1H), 4.48 (t, J=3.6 Hz, 1H), 3.82 (dd, J=7.2, 10.4 Hz, 1H), 3.52 (dd,

J=7.2, 10.0 Hz, 1H), 2.99 (m, 1H), 2.88 (m, 2H), 2.69 (m, 2H), 2.18 (dd,

J=11.2, 13.6 Hz, 1H), 1.94 (m, 2H), 1.12 (s, 9H), 0.98 (s, 9H); 13C NMR (100 MHz, CDCl3)

δ 194.9, 153.5, 152.1, 143.9, 135.9, 135.8, 134.1, 129.9, 129.6, 128.3,

127.9, 127.0, 126.7, 125.1, 124.6, 123.2, 122.0, 87.9, 77.6, 77.2,

76.9, 74.6, 70.4, 63.5, 57.3, 42.8, 35.0, 30.7, 30.5, 29.9, 28.7, 27.1,

19.4; Anal. Calcd for C48H54N4O4SSi: C, 71.08; H, 6.71; N, 6.91; S, 3.95. Found: C, 71.14; H, 6.75; N, 6.95; S, 4.01.

To

a solution of the thiocarbonate obtained above (13.82 g, 17.0 mmol) in

toluene (200 ml) were added tri-n-butyltinhydride (9.4 ml, 34.1 mmol)

and 2,2′-azo-bis-isobutyronitrile (4.32 g, 26.3 mmol), and the reaction

mixture was stirred at 110° C. for 1 hour. After the mixture was cooled

down, the solvent was removed. The resulting residue was purified by

silica gel column chromatography (hexane/ethyl acetate=3/1) to give the

compound 9 (9.21 g, 82%) as a white foam.

UV (MeOH) λmax 272.50 nm; [α]20 D −10.00 (c 0.20, MeOH); HR-MS (ESI): m/z calcd for C41H51N4O2Si [M+H]+: 659.3781; Found: 659.3757; 1H NMR (400 MHz, CDCl3)

δ 8.41 (s, 1H), 7.69 (m, 4H), 7.41 (m, 6H), 7.29 (m, 2H), 7.23 (m, 2H),

6.92 (d, J=3.6 Hz, 1H), 6.31 (d, J=3.6 Hz, 1H), 5.90 (dd, J=7.2, 14.8

Hz, 1H), 5.38 (m, 1H), 5.15 (br s, 1H), 4.33 (dd, J=5.2, 8.4 Hz, 1H),

3.88 (dd, J=6.4, 10.0 Hz, 1H), 3.68 (dd, J=7.2, 10.4 Hz, 1H), 3.05 (m,

1H), 2.96 (dd, J=7.6, 15.6 Hz, 1H), 2.76 (m, 1H), 2.45 (d, J=5.2 Hz,

1H), 2.29 (m, 2H), 2.06 (m, 1H), 1.95 (m, 2H), 1.55 (s, 1H), 1.13 (s,

9H), 1.06 (s, 9H);13C NMR (100 MHz, CDCl3) δ

156.3, 151.9, 144.1, 143.9, 135.9, 135.8, 134.3, 129.8, 128.2, 127.8,

127.0, 125.1, 124.6, 121.8, 77.6, 77.2, 76.7, 73.5, 72.2, 63.6, 56.4,

52.8, 46.8, 42.8, 34.9, 34.5, 30.5, 28.6, 27.2, 28.7, 19.4; Anal. Calcd

for C41H50N4O2Si: C, 74.73; H, 7.65; N, 8.30. Found: C, 74.79; H, 7.61; N, 8.25.

Step 7: Preparation of 2-tert-butoxy-4-[4-(indan-1-ylamino)-pyrrolo[2,3-d]pyrimidin-7-yl]-cyclopentanol (Compound 10)

To

a solution of the compound 9 (9.21 g, 13.97 mmol) in the mixture of THF

and pyridine (1:1, 160 ml) was added dropwise pyridine hydrofluoride

(18.42 ml, 190.0 mmol) at 0° C., and the reaction mixture was stirred at

room temperature for 1 hour. The mixture was neutralized with saturated

aqueous NaHCO3 solution and partitioned between ethyl acetate and water. The organic layer was washed with brine, dried with anhydrous MgSO4,

filtered, and evaporated. Then, the residue was purified by silica gel

column chromatography (hexane/ethyl acetate=1/3) to give the compound 10

(5.63 g, 99%) as a white foam.

UV (MeOH) λmax 273.00 nm; [α]20 D −6.36 (c 1.10, MeOH); HR-MS (ESI): m/z calcd for C25H33N4O2 [M+H]+: 421.2604; Found: 421.2599; 1H NMR (400 MHz, CDCl3)

δ 8.34 (s, 1H), 7.30 (d, J=7.6 Hz, 1H), 7.22 (d, J=7.2 Hz, 2H), 7.15

(t, J=6.8 Hz, 1H), 6.88 (d, J=3.2 Hz, 1H), 6.23 (d, J=3.6 Hz, 1H), 5.83

(dd, J=7.2, 15.2 Hz, 1H), 5.28 (m, 1H), 5.06 (m, 1H), 4.47 (dd, J=5.6,

10.4 Hz, 1H), 3.78 (m, 1H), 3.70 (m, 1H), 3.24 (t, J=5.2 Hz, 1H), 2.98

(m, 1H), 2.87 (m, 1H), 2.68 (m, 1H), 2.46 (m, 1H), 2.37 (m, 2H), 1.93

(m, 2H), 1.18 (s, 9H); 13C NMR (100 MHz, CDCl3) δ

156.2, 151.8, 147.9, 143.9, 143.9, 128.3, 126.9, 125.1, 124.5, 121.9,

97.7, 77.6, 77.2, 76.9, 75.5, 74.9, 63.4, 56.4, 53.8, 44.2, 42.2, 34.9,

33.2, 30.5, 28.6; Anal. Calcd for C25H32N4O2: C, 71.40; H, 7.67; N, 13.32. Found: C, 71.46; H, 7.60; N, 13.35.

Step

8: Preparation of sulfamic acid

2-tert-butoxy-4-[4-(indan-1-ylamino)-pyrrolo[2,3-d]pyrimidin-7-yl]-cyclopentylmethyl

ester (Compound 11)

Preparation

of 2.0 M solution of chlorosulfonamide in acetonitrile: Formic acid

(14.15 ml, 166.0 mmol) was added dropwise to chlorosulfonyl isocyanate

(32.0 ml, 162.5 mmol) under nitrogen atmosphere at 0° C. When the

addition was completed, the mixture was solidified. To the mixture was

added acetonitrile (61.3 ml), and the resulting solution was left to

stand under nitrogen source at room temperature overnight.

To

a solution of the compound 10 (5.63 g, 13.83 mmol) and triethyl amine

(9.7 ml, 0.74 mmol) in acetonitrile (278 ml) was added 2.0 M solution of

chlorosulfonamide in acetonitrile (13.83 ml, 27.76 mmol) at 0° C., and

the reaction mixture was stirred at room temperature for 45 minutes.

Additional 2.0 M chlorosulfonamide solution in acetonitrile (13.83 ml,

27.76 mmol) was added and the mixture was stirred at room temperature

for 15 minutes. The reaction was quenched with methanol, and the solvent

was removed. The residue was purified by silica gel column

chromatography (methylene chloride/methanol=20/1) to give the compound

11 (6.37 g, 92%) as a white foam.

UV (MeOH) λmax 273.00 nm; [α]20 D −18.00 (c 0.50, MeOH); HR-MS (ESI): m/z calcd for C25H34N5O4S [M+H]+: 500.2332; Found: 500.2331; 1H NMR (400 MHz, CDCl3)

δ 8.38 (s, 1H), 7.36 (d, J=7.2 Hz, 1H), 7.29 (d, J=7.2 Hz, 1H), 7.22

(m, 2H), 6.95 (d, J=3.6 Hz, 1H), 6.31 (d, J=3.2 Hz, 1H), 5.89 (d, J=6.4

Hz, 1H), 5.10 (s, 2H), 4.41 (m, 2H), 4.26 (m, 1H), 3.05 (m, 1H), 2.94

(m, 1H), 2.76 (m, 2H), 2.27 (m, 3H), 2.06 (m, 1H), 1.97 (m, 1H), 1.76

(br s, 1H); 13C NMR (100 MHz, CDCl3) δ 156.4,

151.9, 149.9, 143.9, 143.8, 128.3, 126.9, 125.1, 124.5, 121.9, 121.9,

103.5, 97.9, 77.4, 77.2, 76.9, 74.3, 71.9, 71.3, 56.4, 53.1, 49.0, 42.3,

34.9, 34.3, 30.5, 28.6; Anal. Calcd for C25H33N5O4S: C, 60.10; H, 6.66; N, 14.02; S, 6.42. Found: C, 60.15; H, 6.71; N, 13.98; S, 6.39.

Step

9: Preparation of sulfamic acid

2-hydroxy-4-[4-(indan-1-ylamino)-pyrrolo[2,3-d]pyrimidin-7-yl]-cyclopentylmethyl

ester (Compound 1)

A

solution of the compound 11 (6.37 g, 12.72 mmol) in 70% trifluoroacetic

acid (149.24 ml) was stirred at room temperature for 2 hours. The

solvent was removed and the residue was purified by silica gel column

chromatography (hexane/ethylene acetate=1/2) to give the compound 1

(5.08 g, 90%) as a white foam. BASE

UV (MeOH) λmax 279.50 nm; [α]20 D −6.41 (c 2.34, MeOH);

HR-MS (ESI): m/z calcd for C21H26N5O4S [M+H]+: 444.1705; Found: 444.1706;

1H NMR (400 MHz, CD3OD)

δ 8.17 (d, J=1.6 Hz, 1H), 7.25 (m, 2H), 7.18 (m, 2H), 6.64 (d, J=3.6

Hz, 1H), 5.86 (t, J=7.6 Hz, 1H), 5.46 (m, 1H), 4.49 (d, J=2.8 Hz, 1H),

3.07 (m, 1H), 2.92 (m, 1H), 2.80 (m, 1H), 2.64 (m, 1H), 2.35 (m, 1H),

2.25 (m, 2H), 2.03 (m, 2H);

13C NMR (100 MHz, CD3OD) δ 152.1, 145.3, 144.6, 128.8, 127.6, 125.7, 125.2, 122.6, 100.5, 73.1, 70.9, 56.9, 54.0, 44.8, 43.6, 34.9, 34.6, 31.1;

Anal. Calcd for C21H25N5O4S: C, 56.87; H, 5.68; N, 15.79; S, 7.23. Found: C, 56.91; H, 5.73; N, 15.82; S, 7.26.

.........................

http://www.google.com/patents/WO2010132110A1?cl=en

((lS,2S,4R)-4-{4-[(lS)-2,3-dihydro-lH-inden-l-ylamino]-7H-pyrrolo[2,3-d]pyrimidin-7-yl

}-2-hydroxycyclopentyl)methyl sulfamate (//) is described in Intl. App.

Pub. No. WO 07/092213, U.S. App. Pub. No. 2007/0191293, and U.S. App.

Pub. No. 2009/0036678. The potassium salt of ((lS,2S,4R)-4-{4-[( 1

S)-2,3-dihydro- 1 H-inden- 1 -ylamino]-7H-pyrrolo[2,3-d]pyrimidin-7-yl }

-2-hydroxycyclopentyl)methyl sulfamate is disclosed in Intl. App. Pub.

No. WO 07/092213 and U.S. App. Pub. No. 2007/0191293.

(H)

((lS,2S,4R)-4-{4-[(lS)-2,3-dihydro-lH-

inden-l-ylamino]-7H-pyπOlo[2,3-d]pyrimidin-7-yl}-2-hydroxycyclopentyl)methyl

sulfamate (/):

Step

3: Synthesis of

((lS,2S.4R)-4-(4-r(lS)-2,3-dihydro-lH-inden-l-ylaminol-7H-pyrrolor2.3-dlpyrimidin-7-yl}-2-hvdroxycvclopentyl)methyl

sulfamate hydrochloride Form 1

[0158] A reactor was charged with

((lS,2S,4R)-4-{4-[(lS)-2,3-dihydro-lH-inden-l-ylarnino]-7H-pyrrolo[2,3-d]pyrimidin-7-yl

}-2-hydroxycyclopentyl)methyl sulfamate (13.4 Kg, 30.2 mol) and

200-proof ethanol (106.2 Kg). The mixture was heated to reflux to afford

a clear solution. The mixture was cooled to 50 ± 5 0C and

passed through a cartridge filter. 200 proof ethanol (8.9 Kg) was used

to rinse the filter. 1.27M hydrogen chloride in ethanol (10.2 Kg) was

added via a cartridge filter at a rate to maintain a temperature of 50 ±

5 0C. The mixture was then seeded with Form 1 (67 g).

Further 1.27M HCl (10.2 Kg) was added via a cartridge filter at a rate

to maintain a temperature of 50 ± 5 0C. The mixture was then stirred at 50 ± 5 0C for about 3 hours. The mixture was then cooled to 20 ± 5 0C

over about 3 hours and then stirred for about 2.5 hours. The solid

product was then isolated by filtration and washed with 200-proof

ethanol (I x 20.4 Kg and 1 x 21.2 Kg). The solids were dried by

aspiration on the filter until no supernatant was seen to be collected,

and then further dried under reduced pressure at <30 0C to

afford the title compound (12.2 Kg) as a white solid determined to be

Form 1 by XRPD. IH NMR (300MHz, DMSO, δ): 9.83 (s, IH), 8.34 (s, IH),

7.62 (s, IH), 7.44 (s, 2H), 7.30 (m, 3H), 7.22 (t, IH), 7.07 (s, IH),

5.86 (dd, IH), 5.42 (m, IH), 4.32 (m, IH), 4.21 (dd, IH), 4.02 (dd, IH),

3.04 (m, IH), 2.88 (m, IH), 2.67 (m, 2H), 2.15 (m, 2H), 2.08 (m, 2H),

1.94 (m, IH). XRPD data for Form 1 is shown in FIGURE 1 and Table 1; DSC

data is shown in FIGURE 2, and TGA data for Form 1 is shown in FIGURE

3.

..............

http://www.google.com/patents/WO2007092213A2?cl=en

Example 70: Diastereoisomeric mixture of (lS

/2R

/4R)-4-{4-[(lS)-2

/3-dihydro-lH-inden-l- ylaimnol-ZH-pyrrolop^-dlpyxirnidin-Z-ylJ^-hydroxycyclopentyl s ulf amate and (lR

f2S

/4S)-4-{4-[(lS)-2,3-dihydro-lH-inden-l-ylaminol-7H-pyrrolo[2,3d]-

pyrimidin-7-yl}-2-hydroxycyclopentyl sulfamate (Compounds 1-77 and

1-78)

Step a: Cyclopent-3-en-l-yl methanesulfonate

[0335] 3-Cydopentene-l-ol (0.500 g, 5.94 mmol) was stirred in DCM (95 mL).

Pyridine

(2.40 mL), N,N-dimethylaminopyridine (0.10 g, 1.00 mmol) and

methanesulfonyl chloride (0.690 mL, 8.92 mmol) were added, and the

reaction mixture was stirred at 35

0C for 4 h.

N,N-Dimethylarrιinopyridirιe (0.14 g, 1.2 mmol) and methanesulfonyl

chloride (0.69 mL, 8.92 mmol) were added, and the reaction was stirred

overnight. TLC indicated complete conversion. The reaction mixture was

cooled and concentrated. The residue was purified by silica gel

chromatography, eluting with DCM, to afford the title compound as a

clear oil (0.660 g, 68%).

Step b: 7-Cyclopent-3-en-l-yl-N-r(lSV2,3-dihydro-lH-inden-l-yn-7H-pyrrolor2,3-rfl- pyrmτidin-4-arnine

[0336] N-[(lS)-2,3-DihydrcHlH-mden-l-yl]-7H-pyrrolo[2

/3-d]p3αimidin-4-amine

(1.32 g, 5.29 mmol) was azeotroped with toluene and placed under high

vacuum for 30 min. N,N-Dimethylformamide (17.7 mL) was added, followed

by cesium carbonate (1.99 g, 6.10 mmol). The mixture was stirred at 70

0C

for 10 min. Cyclopent-3-en-l-yl methanesulfonate (0.660 g, 4.07 mmol)

in N,N-dimethylformarnide (12.6 mL) was added dropwise. The reaction

mixture was heated to 110

0C for 1 h. The reaction mixture was cooled, quenched with brine and diluted with H

2O. The aqueous layer was extracted with EtOAc (3x), washed with H

2O and brine, dried (Na

2SO

4),

filtered, and concentrated. The residue -was purified by via silica gel

chromatography, eluting with a gradient of 0 to 5% MeOH in DCM followed

by 25 to 50% EtOAc in hexanes, to afford the title compound as a pale

brown solid (0.684 g, 53%). LC/MS: R

1 = 1.38 min, ES

+

317 (FA standard). Step c:

(lR,2S,45)-4-{4-r(lS)-2,3-dihydro-lH-inden-l-ylaininol-7H-pyrrolof2.3-

rf1pyrimidin-7-yl}cyclopentane-l,2-diol

[0337]

7-Cyclopent-3-en-l-yl-N-[(lS)-2^-dihyrdo-lH-inden-l-yl]-7H-pyrrolo[2,3-

d]pyτimidin-4-amine (0.312 g, 0.986 mmol) was stirred in tert-butyl

alcohol (4.9 mL) and H

2O (4.9 mL). AD-mix-α (Sigma- Aldrich,

1.4 g) was added, and the suspension was stirred at rt overnight. TLC

indicated complete conversion. The reaction was quenched with sodium

sulfite (1.48 g, 11.7 mmol), and the mixture was stirred for 5 h. The

reaction mixture was diluted with EtOAc and H

2O, and the aqueous layer was extracted with EtOAc (2x). The organic layer was dried (Na

2SO

4),

filtered, and concentrated. The residue was purified via silica gel

chromatography, eluting with EtOAc, to afford the title compound as a

white solid (0.190 g, 55%).

Step d: Diastereoisomeric mixture of

(lS,2R,4R)-4-{4-r(15)-23-dihydro-lH-inden-l-

ylarninoi^jH-pyrrolofΣ^dlpyrirnidin-y-yll-l-hydroxycyclopentyl sulfamate

and

(lR,2S,4S)-4-{4-iαSV2,3-dihydro-lH-inden-l-ylarninol-7H-pyrrolor2,3-

rf1pyrimidm-7-yl)-2-hydroxycyclopenryl sulfamate (Compounds 1-77 and

1-78)

[0338] (lR,2S,4S)-4-{4-[(lS)-2,3-Dihydro-lH-inden-l-ylarnino]-7H-pyrrolo[2

/3-

d]pyrimidin-7-ylJcyclopentane-l,2-diol (0.080 g, 0.23 mmol) was

azeotroped with toluene and then was dissolved in anhydrous acetonitrile

(2.3 mL). Pyridine (0.0369 mL, 0.458 mmol) was added. The reaction

mixture was cooled to 0

0C, and a 2N solution of

chlorosulfonamide in acetonitrile (0.144 mL) was added dropwise. The

reaction was stirred for 1 h, and then additional 2N chlorosulfonamide

in acetonitrile (0.028 mL) was added. After 30 min, additional 2N

chlorosulfonamide in acetonitrile (0.0342 mL) was added, and the

reaction mixture was stirred for 2 h. The reaction was quenched with

methanol, and the mixture was concentrated in vacuo. The residue was

purified by preparative thin layer chromatography using DCM:AcCN:MeOH

(50:45:5). The relevant band was cut, washed with acetone, filtered, and

concentrated to give a mixture of diastereomers as a white solid. (11

mg, 11%).

1H NMR (CDCl

3, 400 NMR, δ): 8.36-8.27

(m, IH); 7.38-7.09 (m, 5H); 6.90-6.80 (m, IH); 6.36- 6.20 (m, IH);

5.95-5.76 (m, IH); 5.51-5.22 (m, 2H); 4.83-4.68 (m, IH); 3.87-3.72 (m,

IH); 3.12- 2.83 (m, 2H); 2.75-2.53 (m, IH); 2.50-2.14 (m, 2H); 2.08-1.79

(m, 2H) ppm. LC/MS: R, = 1.16 min, ES

+ 430 (FA standard).

............

WO 2012061551

http://www.google.im/patents/WO2012061551A1?cl=en

The

compound

((lS,2S,4R)-4-(4-((lS)-2,3-dihydro-lH-inden-l-ylamino)-7H-pyrrolo[2,3-d]-

pyrimidin-7-yl)-2-hydroxycyclopentyl)methyl sulfamate:

also

known as MLN4924, is an inhibitor of NEDD8-activating enzyme (NAE).

Inhibition of NAE has been shown to induce cancer cell death and inhibit

the growth of tumors in xenograft models. See, e.g., T.A. Soucy et al.,

Nature, 2009, 458, 732-737; T.A. Soucy ei al., Clin. Cancer Res., 2009,

15 (12), 3912-3916; and J.E. Brownell et al., Mol. Cell., 2010, 37 (1),

102-111, each of which is hereby incorporated by reference herein in

its entirety. MLN4924, pharmaceutical compositions of MLN4924, processes

for its synthesis, and polymorphic forms have been described

previously. See, e.g., US Patent Appl. Nos. 11/700,614 (Publ. No.

2007/0191293), 12/221,399 (Publ. No. 2009/0036678) and 12/779,331 (Publ.

No. 2011/0021544),

...............

Org. Process Res. Dev., Article ASAP

A

practical synthesis of a novel NEDD8-activating enzyme (NAE) inhibitor

pevonedistat (MLN4924) is described. Key steps include an

enantioselective synthesis of an amino-diol cyclopentane intermediate

containing three chiral centers and a novel, regioselective

sulfamoylation using N-(tert-butoxycarbonyl)-N-[(triethylenediammonium)sulfonyl]azanide.

The linear process, involving six solid isolations, has been carried

out in multiple cGMP productions on 15–30 kg scale to produce

pevonedistat in 98% (a/a) chemical purity and 25% overall yield.

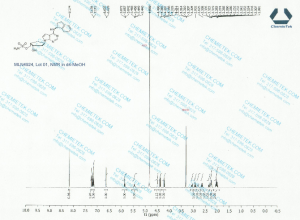

((1S,2S,4R)-4-(4-(((S)-2,3-Dihydro-1H-inden-1-yl)amino)-7H-pyrrolo[2,3-d]pyrimidin-7-yl)-2-hydroxycyclopentyl)methyl Sulfamate (1)

The reaction yielded 1 (0.285 kg, 58.5%, 93.0% a/a) as an off-white solid.

HPLC retention time of 1 BASE(Method C): 22.6 min;

1H NMR (400 MHz, DMSO) δ 8.19 (s, 1H), 7.77 (d, J = 8.4 Hz, 1H), 7.45 (s, 2H), 7.31–7.26 (m, 2H), 7.22 (t, J = 6.6 Hz, 2H), 7.15 (t, J = 7.2 Hz, 1H), 6.66 (d, J = 3.5 Hz, 1H), 5.92 (q, J = 8.0 Hz, 1H), 5.39 (qd, J = 8.8, 5.7 Hz, 1H), 4.95 (d, J = 3.9 Hz, 1H), 4.42–4.31 (m, 1H), 4.25 (dd, J = 9.7, 7.0 Hz, 1H), 4.07 (dd, J = 9.6, 8.0 Hz, 1H), 3.01 (ddd, J = 15.7, 8.7, 3.0 Hz, 1H), 2.95–2.81 (m, 1H), 2.81–2.65 (m, 1H), 2.58–2.49 (m, 1H), 2.31–1.86 (m, 5H);

13C

NMR (100 MHz, DMSO) δ 155.91, 151.18, 149.02, 144.66, 142.98, 127.30,

126.28, 124.49, 124.11, 121.68, 102.83, 98.86, 70.82, 69.37, 54.48,

52.15, 42.58, 42.25, 33.50, 33.26, 29.72;

m/z: 444.4 (M + H)+;

mp: 164–166 °C.

((1S,2S,4R)-4-(4-(((S)-2,3-Dihydro-1H-inden-1-yl)amino)-7H-pyrrolo[2,3-d]pyrimidin-7-yl)-2-hydroxycyclopentyl)methyl Sulfamate·Hydrochloride (Pevonedistat)

Pevonedistat (14.0 g, 92.5%, 99.0% a/a) as a white solid.

HPLC retention time of pevonedistat (Method C): 22.6 min;

1H

NMR (400 MHz, DMSO) δ 9.70 (s, 1H), 8.39 (s, 1H), 7.63 (s, 1H), 7.45

(s, 2H), 7.41–7.20 (m, 4H), 7.04 (s, 1H), 5.78 (s, 1H), 5.44 (s, 1H),

4.42–4.28 (m, 1H), 4.24 (dd, J = 9.7, 6.9 Hz, 1H), 4.05 (dd, J = 9.6, 8.0 Hz, 1H), 3.18–2.99 (m, 1H), 2.91 (dt, J = 15.6, 7.7 Hz, 1H), 2.81–2.57 (m, 2H), 2.24–1.86 (m, 6H).

13C

NMR (100 MHz, DMSO) δ 149.12, 145.71, 143.23, 142.11, 141.30, 128.28,

126.64, 124.97, 124.82, 124.49, 102.57, 101.74, 70.67, 69.22, 57.38,

53.14, 42.52, 42.40, 33.57, 32.56, 29.80;

m/z: 444.4 (M + H)+;

mp: 155–157 °C.

.................

J. Org. Chem., 2011, 76 (9), pp 3557–3561

DOI: 10.1021/jo2001897

MLN4924 (1), which is in clinical trials as an anticancer agent, was stereoselectively synthesized from d-ribose

via a route involving stereoselective reduction, regioselective

cleavage of an isopropylidene moiety, and selective displacement of a

cyclic sulfate moiety as key steps.

Sulfamic Acid 2-Hydroxy-4-[4-(indan-1-ylamino)pyrrolo[2,3-d]pyrimidin-7-yl]cyclopentylmethyl Ester (1) BASE

purified by silica gel column chromatography (hexane/ethyl acetate = 1/2) to give 1 (5.08 g, 90%) as a white foam:

UV (MeOH) λmax 279.50 nm;

[α]20D −6.41 (c 2.34, MeOH);

HR-MS (ESI) m/z calcd for C21H26N5O4S [M + H]+ 444.1705, found 444.1706;

1H NMR (400 MHz, CD3OD) δ 8.17 (d, J = 1.6 Hz, 1H), 7.25 (m, 2H), 7.18 (m, 2H), 6.64 (d, J = 3.6 Hz, 1H), 5.86 (t, J = 7.6 Hz, 1H), 5.46 (m, 1H), 4.49 (d, J = 2.8 Hz, 1H), 3.07 (m, 1H), 2.92 (m, 1H), 2.80 (m, 1H), 2.64 (m, 1H), 2.35 (m, 1H), 2.25 (m, 2H), 2.03 (m, 2H);

13C NMR (100 MHz, CD3OD)

δ 152.1, 145.3, 144.6, 128.8, 127.6, 125.7, 125.2, 122.6, 100.5, 73.1,

70.9, 56.9, 54.0, 44.8, 43.6, 34.9, 34.6, 31.1. Anal. Calcd for C21H25N5O4S: C, 56.87; H, 5.68; N, 15.79; S, 7.23. Found: C, 56.91; H, 5.73; N, 15.82; S, 7.26.

| WO2012061551A1 * | Nov 3, 2011 | May 10, 2012 | Millennium Pharmaceuticals, Inc. | Administration of nedd8-activating enzyme inhibitor |

| WO2013028832A2 * | Aug 23, 2012 | Feb 28, 2013 | Millennium Pharmaceuticals, Inc. | Inhibitors of nedd8-activating enzyme |

| WO2013028832A3 * | Aug 23, 2012 | May 2, 2013 | Millennium Pharmaceuticals, Inc. | Inhibitors of nedd8-activating enzyme |

| US8809356 | Aug 23, 2012 | Aug 19, 2014 | Millennium Pharmaceuticals, Inc. | Inhibitors of NEDD8-activating enzyme |

| Reference |

|---|

| 1 | * | Lee, et. al., Journal of Organic Chemistry (2011), 76(9), 3557-3561. |

- (1) Lee, Hyuk Woo; Journal of Organic Chemistry 2011, 76(9), P3557-3561

- (2) Soucy, Teresa A.; Nature (London, United Kingdom) 2009, 458(7239), P732-736

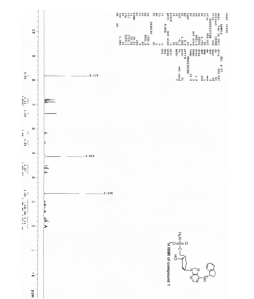

1H NMR PREDICT

CLICK ON PIC FOR CLEAR VIEW

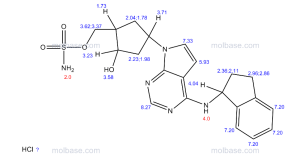

CLICK ON PIC FOR CLEAR VIEW

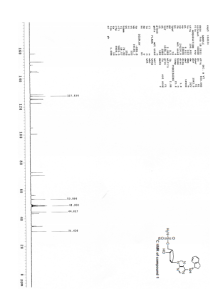

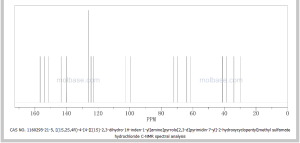

13 C NMR

CLICK ON PIC FOR CLEAR VIEW

CLICK ON PIC FOR CLEAR VIEW

//////////Pevonedistat, MLN4924, Millennium Pharmaceuticals, TAKEDA, TAK-924 , PHASE 1, orphan drug designation

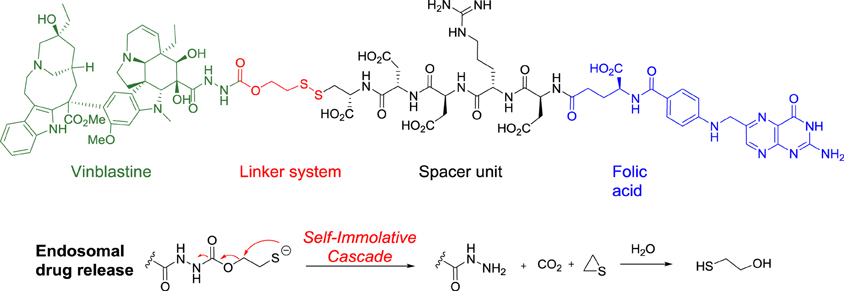

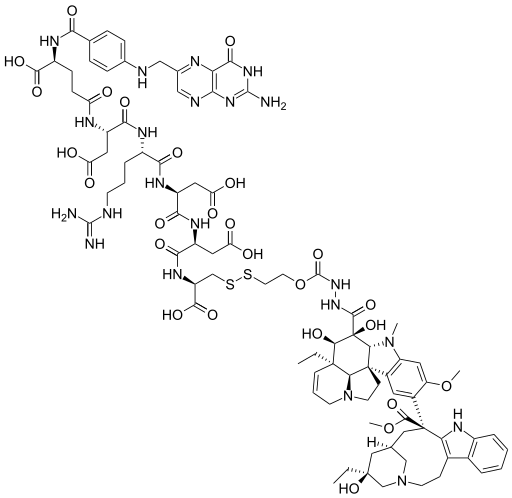

CLICK ON IMAGE FOR CLEAR VIEW

CLICK ON IMAGE FOR CLEAR VIEW